When our customers demand reliable tooling, Huth delivers. We've offered American-made tooling for BendPak®️ bending machines for a long time because customers insisted on it!

We're known for our high-quality benders and tooling at Huth-Ben Pearson International. Our tooling is manufactured here in the U.S.A. to specific tolerances from select grades of solid steel. Our tooling for BendPak®️ and all bending machines is unsurpassed for bending performance and reliability.

The Huth Tooling for BendPak®️ Process

Our tooling is carefully machined with quality steel. After the machining process, we further harden the tooling. The pieces are gas-carburized and oil-quenched to a minimum hardness of 58 Rockwell “C” scale, offering reliable performance time and time again.

Watch to see the difference in Huth's design and quality.

Many customers requested Huth tooling for the BendPak®️ machines in their automotive shops and manufacturing operations. They appreciate that Huth offers a quality product that creates a perfect bend with each use. Customers also appreciate that we keep tooling for BendPak®️ readily available in our shelf stock.

Explore the range of Huth Tooling for BendPak®️.

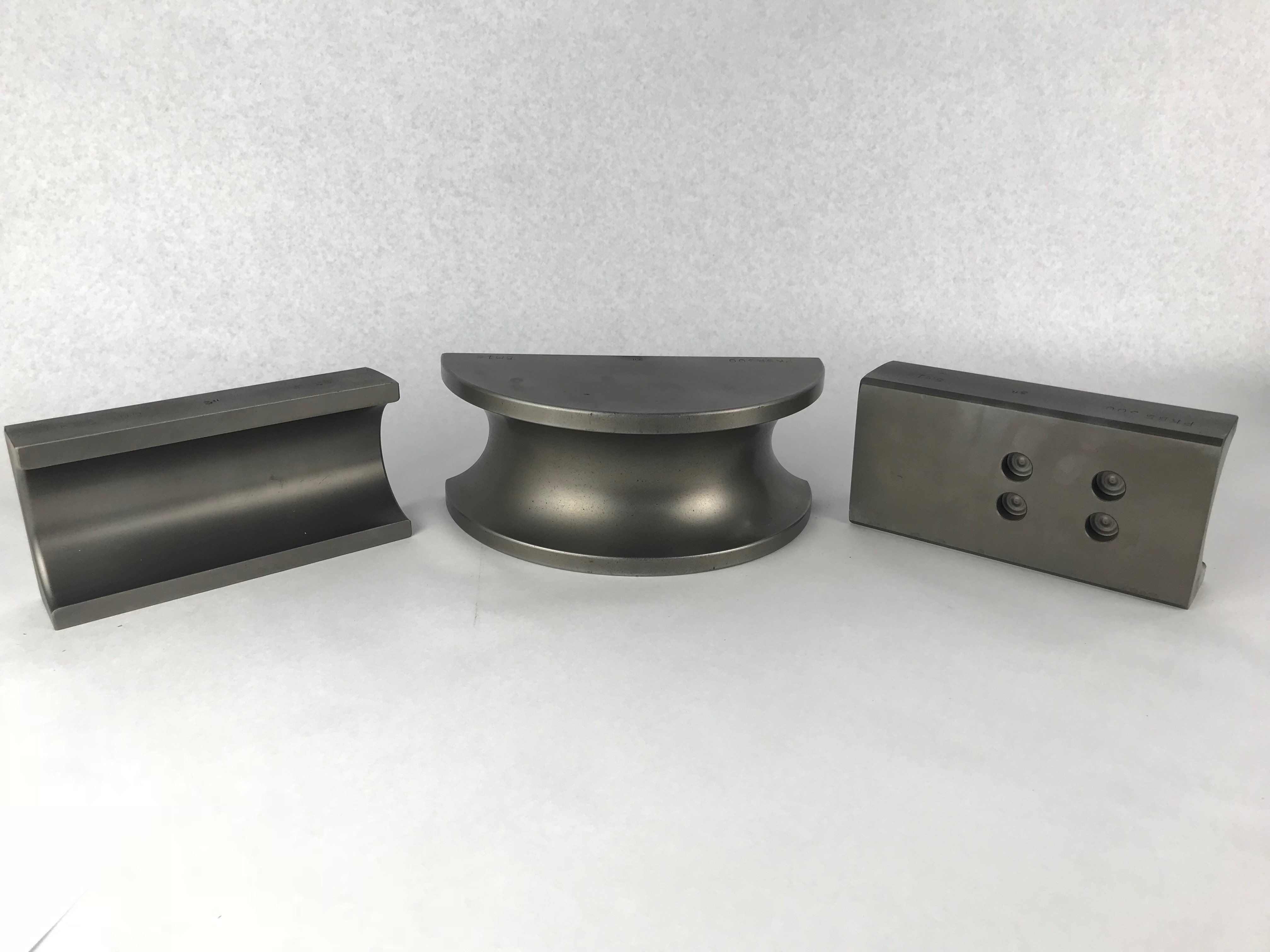

Bending Dies and Back Shoes

Direct Fit 3” Bending Dies

Our bending dies and back shoes are specially designed to offer great bends on 3” OD tubing. BendPak®️ users requested 3” tooling to fit directly on their BendPak®️ benders, and Huth delivered.

If you've seen the video above or worked with any Huth products, you know that Huth is known for superior bending abilities. Our carefully designed tooling performs reliably, especially in the critical bending cavity.

Our direct fit 3” bending dies and back shoes fit the current version of BendPak®️ bending machines. These machines have been on the market since the early 2000s. So, if you're looking for reliable bending dies, these are the perfect update for your BendPak®️ device.

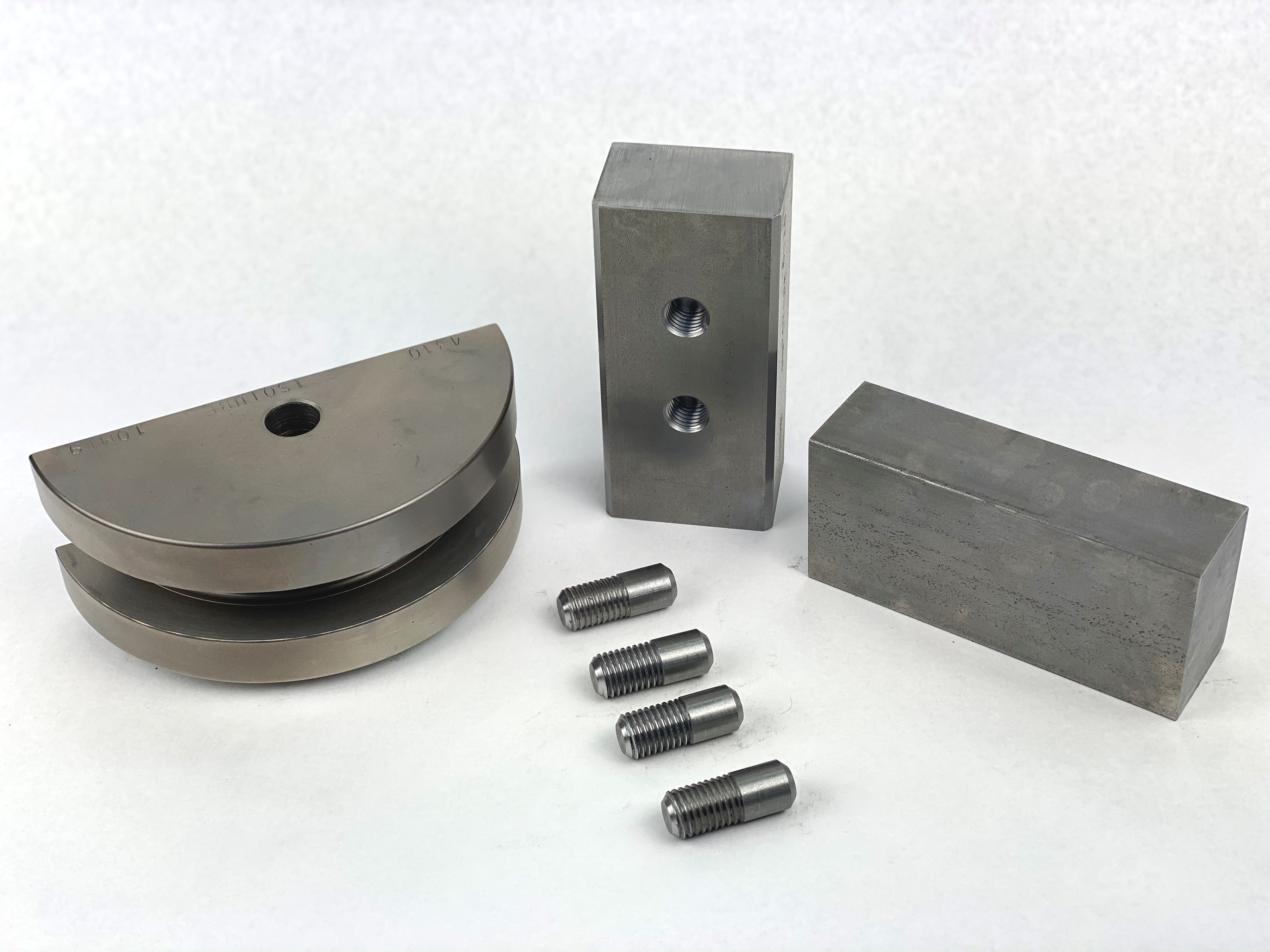

Square Tooling for BendPak®️ Machines

Square tooling is another request from our customers who need to bend square and rectangular pipe and tubing with their BendPak®️.

Square tooling is one of our most popular fits across the board on all bending machines. The bends are ideal for square and rectangular piping used to manufacture carports, sporting goods, and other equipment. After bending, the bend is even stronger than the original piping.

Our square tooling fits BendPak®️ machines with a simple adapter. Square tooling is an excellent option if you want to get more out of your machine.

Part Number 798

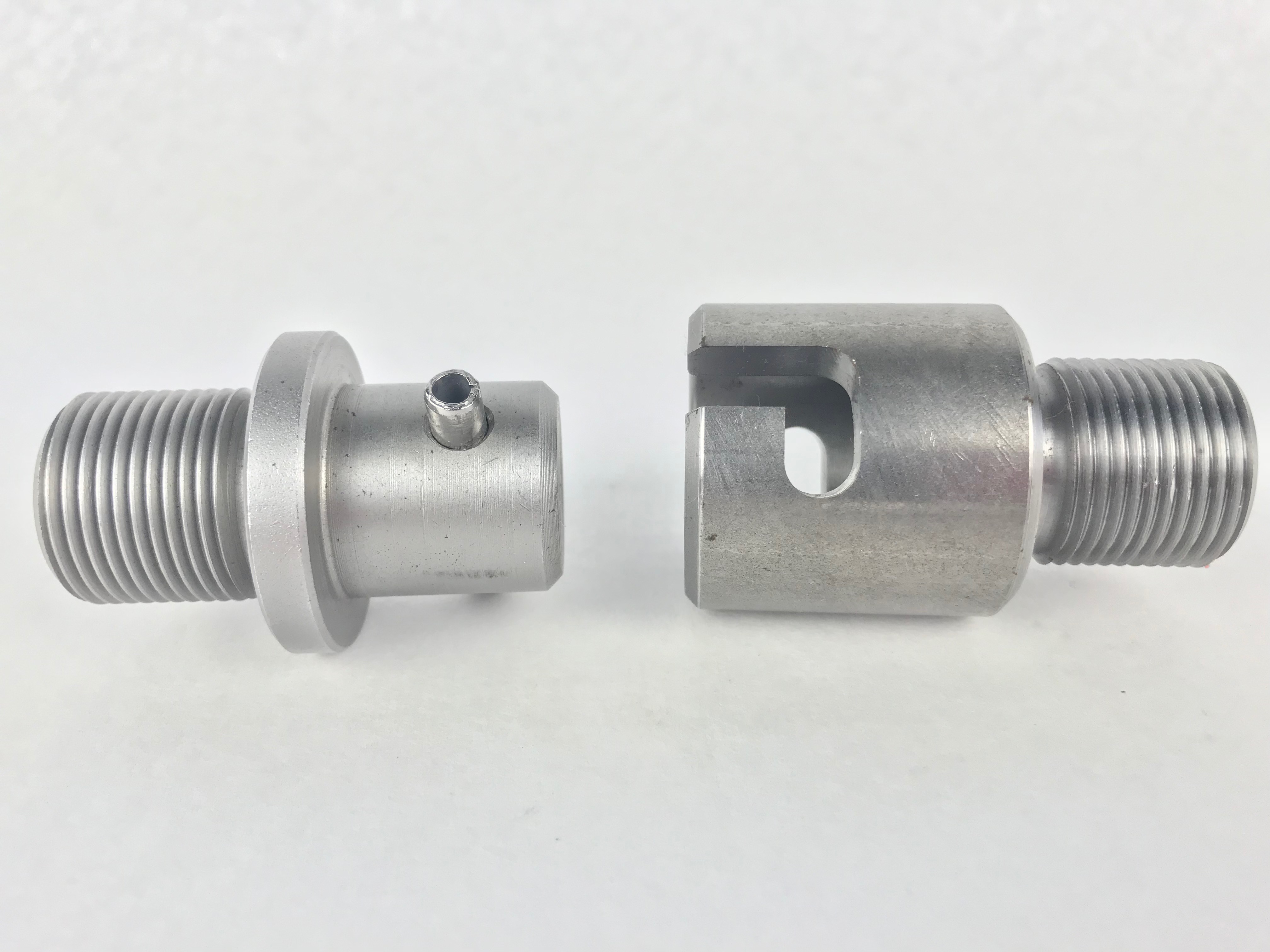

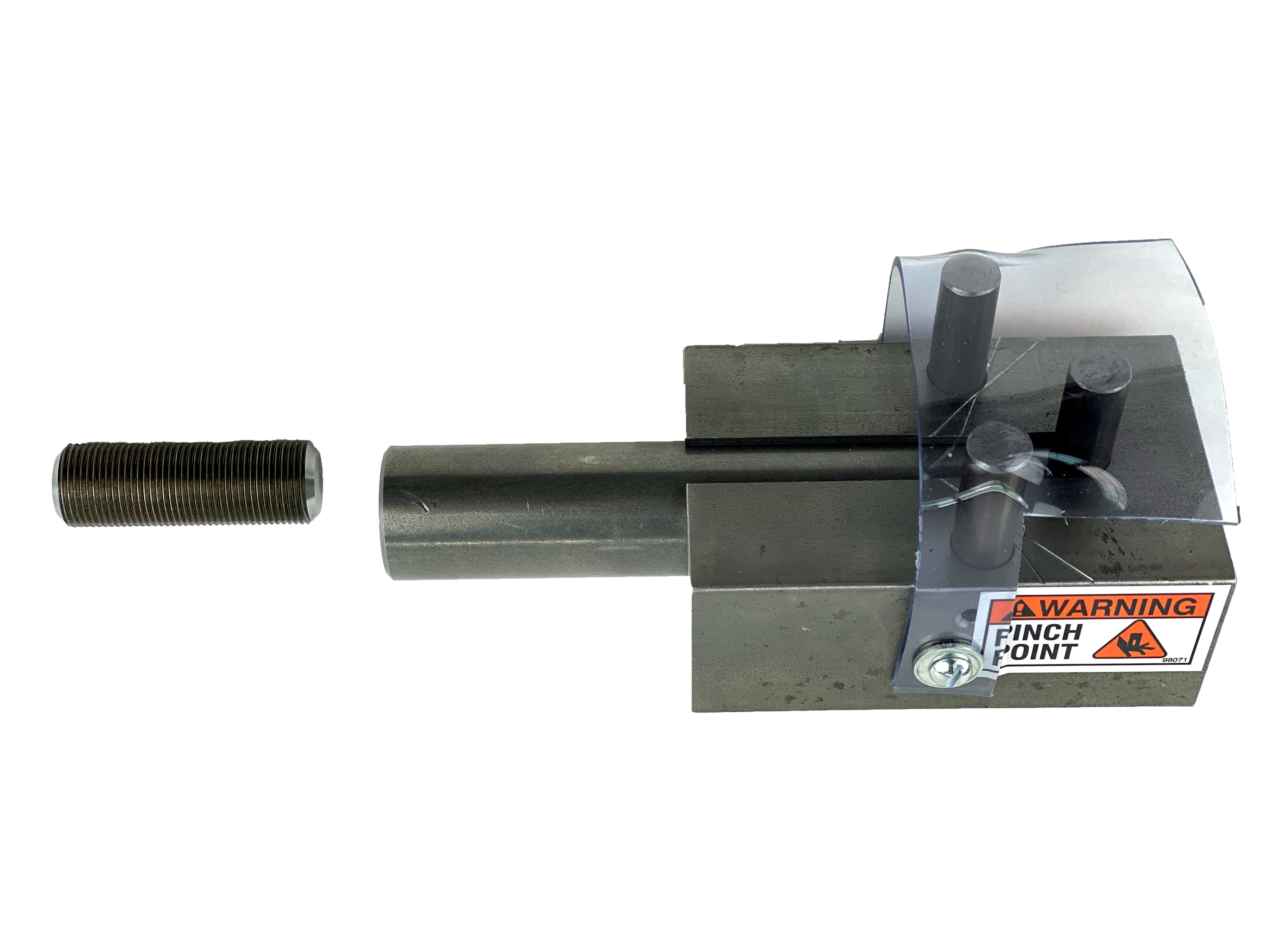

Swager Tooling for BendPak®️ Machines

The Swage Box allows Huth bending machines to form ends that enable you to connect tubes, form joints, and finish pipe ends in many different useful configurations. Customers appreciate the end-forming abilities of Huth Machines.

The Huth Swager tooling for BendPak®️ machines lets our customers use the Huth Swager with their BendPak®️ bender to add end-finishing operations to their repertoire. These simple adapters give you all the advantages of Huth end-forming tooling directly on your existing machine.

Huth PKDS-823 AND PKDF-818 Adapters

Huth Swage Die with the PKDS-823

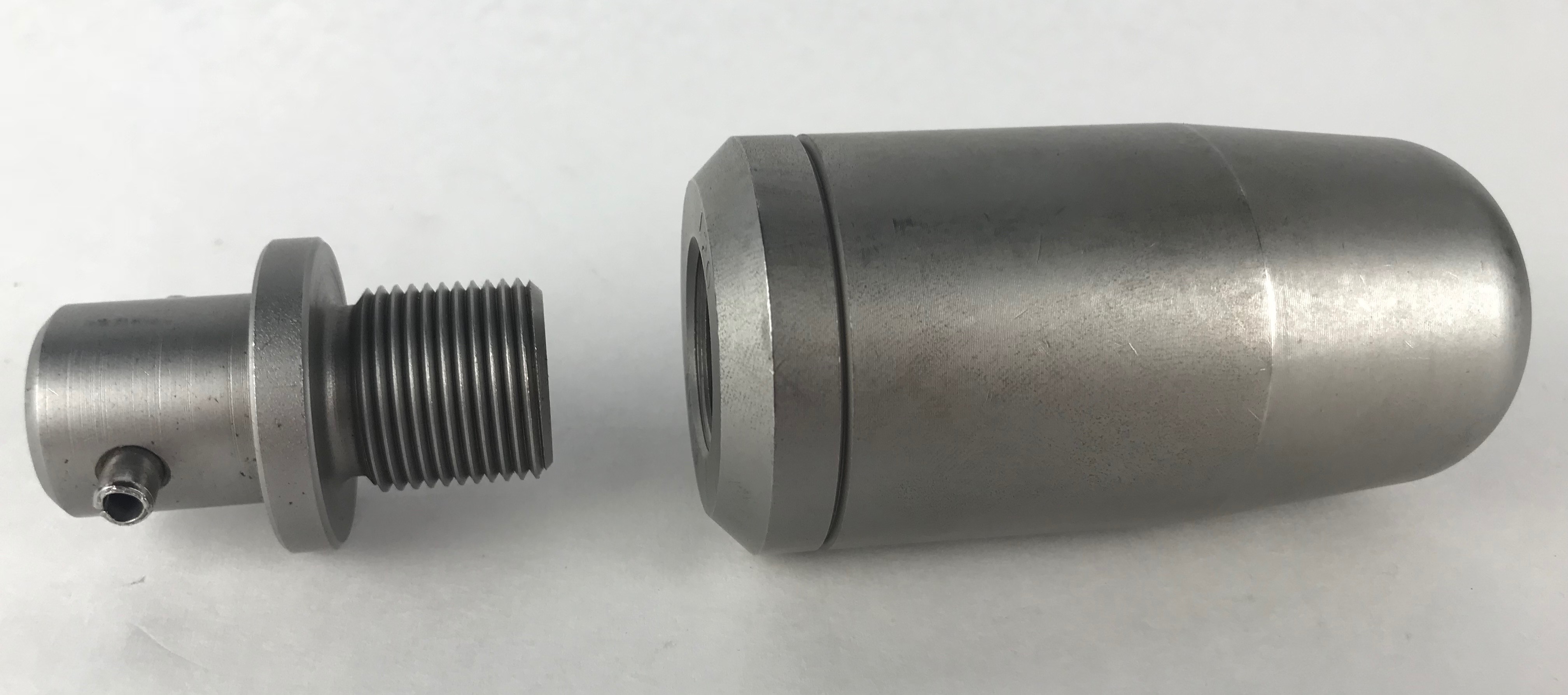

Expander Tooling for Your BendPak®️ Machines

Would you like to do more for your business with your BendPak®️ machine? We offer a wide variety of expander tooling that can increase the abilities and quality of the bends on your BendPak®️ machine.

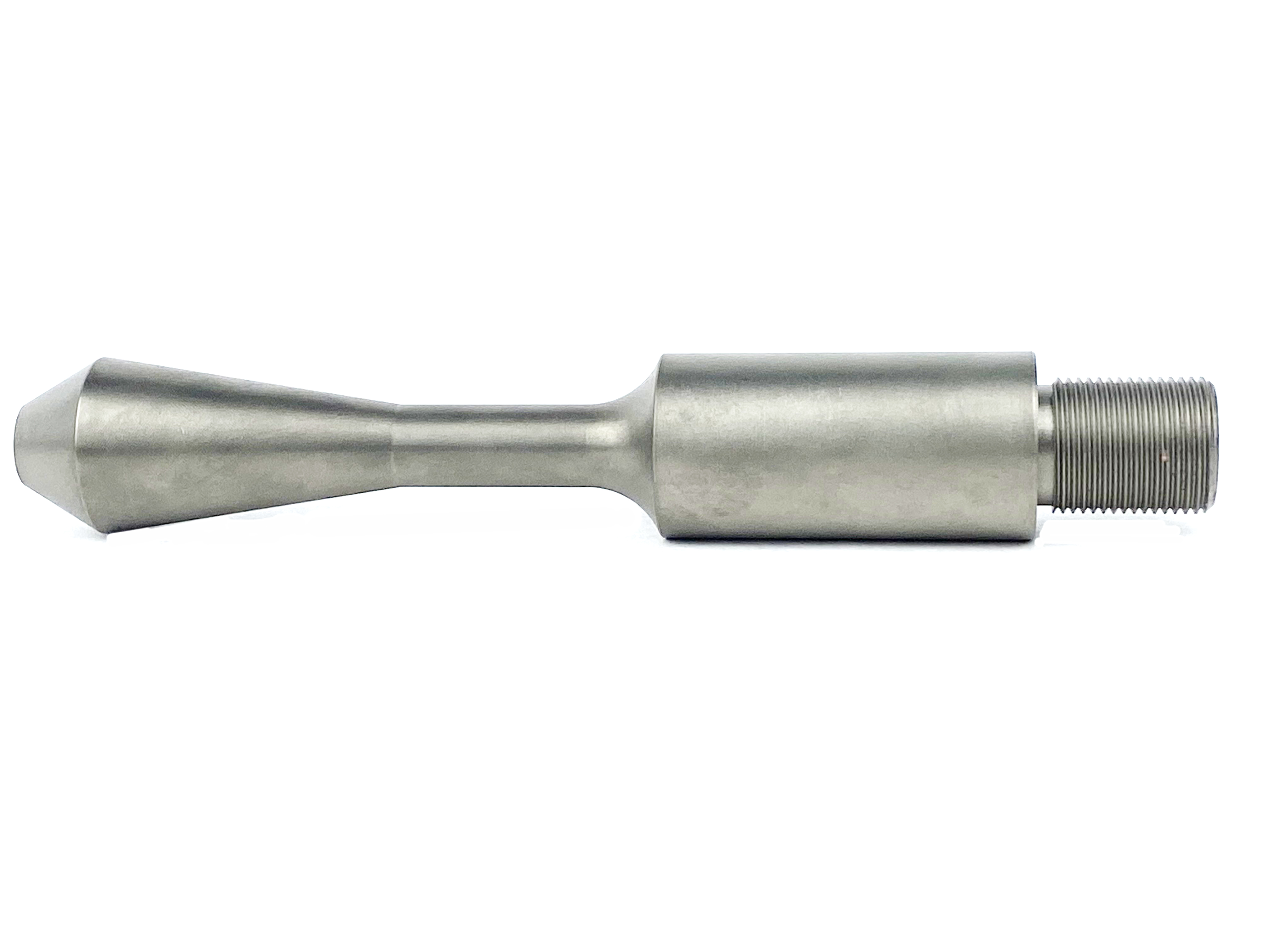

PKSA112 Direct Fit Arbor

Direct Fit Segments to use with the PKSA112 Arbor

Accessories For Your BendPak®️ Machines

Huth-Ben Pearson has been the leading manufacturer and supplier of pipe and tube bending and forming equipment, tooling, and accessories worldwide for over 50 years. All our products are made in America with the most reliable materials.

Thanks to our reputation for quality, customers request Huth accessories and tooling for their BendPak® machines. These handy accessories will help you get the most out of your bender investment and offer more to your customers—like the Rod Bracket Bender with Threaded Stud, which can bend solid rods and brackets easily!

Rod Bracket Bender with Threaded Stud

We have a complete catalog of accessories for BendPak®️ owners available from Huth-Ben Pearson. At Huth, you can rely on us to help you get more from your benders.

BendPak®️ is a registered trademark of BendPak, Inc.